|

When selecting a stormwater attenuation system, sometimes little attention is paid to cleaning and the costs of ongoing maintenance. System maintenance is essential to ensure that the design performance is retained throughout the service life, and that the risks of flooding and pollution are avoided.

This vital part of asset management can be overlooked at both the design and procurement stages, as the choice is often based on the incorrect assumption that all below-ground attenuation systems are equally easy and low cost to maintain.

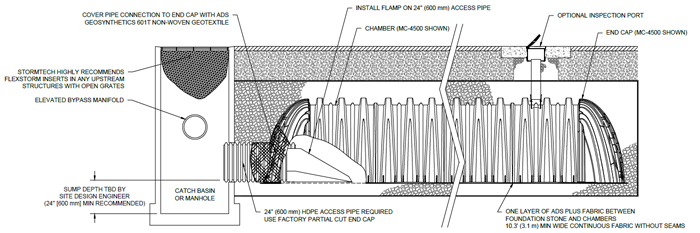

Compared to both crates and large diameter pipes, ADS StormTech is a superior cost- and time- saving solution.

Consider the facts: -

Because of their structure, stormwater attenuation crates are difficult to access and clean, and require upstream silt removal to prevent a downstream build-up of material within the tank body. Whilst pipes are easier than crates to access, they too require upstream intervention for silt and hydrocarbon removal.

Both pipes and crates are therefore dependent on the additional expenditure and maintenance of an upstream silt separation and removal system. If silt gets into the storage tank, it can compromise the flow path and reduce the storage volumes – causing the whole system to fail.

But that’s not all. Silt particles can carry pollutants and if these get into the storage tank, they may flush downstream and result in water quality breaches, pollution, and fines.

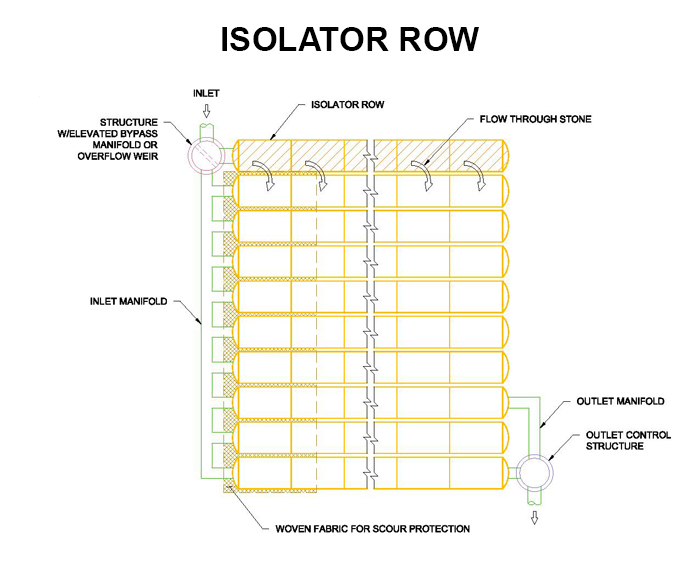

Crates and pipes, therefore, depend heavily on expensive upstream pre-treatment systems which, together with the attenuation tank, require regular inspection and maintenance. ADS StormTech rarely requires upstream silt pre-treatment, therefore reducing capital and operational costs.

|